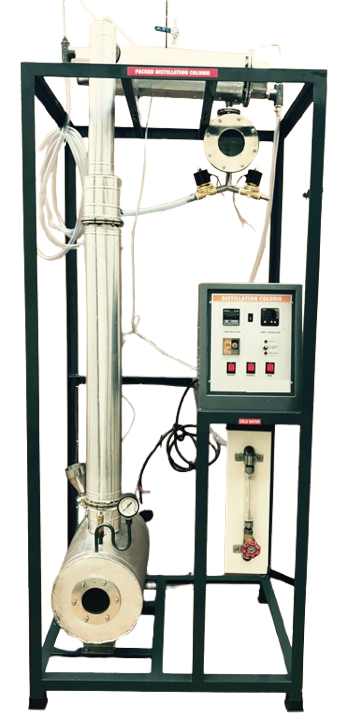

Scieve Plate Distillation Column

The setup is designed to demonstrate principles of distillation in a Sieve Plate Column. The column is made of Stainless Steel material with seven sieve trays. An electrically heated re-boiler is installed at the bottom of the column. The vapors from the top of column are condensed in the shell and tube type condenser by circulating cooling water and it is supplied by laboratory overhead tank. The condensate is divided into reflux & distillate and R/D Ratio can be varied. Reflux is fed back to the column and distillate is received in a receiving tank. The complete column is insulated for minimizing the heat loss. Instrumentation is done for pressure & temp.

Technical Specification :-

| Rotameter |

For cooling water flow rate measurement.

|

| Distillate Tank |

Made of Stainless Steel, capacity 5 Ltrs.

|

| Heaters |

Nichrome wire heater.

|

| Steam Generator |

Made of Stainless Steel, provided with Pressure Gauge & Level Indicator

|

| Reflux Divider |

Special arrangement to change R/D ratio automatically.

|

| Temperature Sensors |

RTD PT-100 type.

|

| Distillation Column |

Material Stainless Steel, Dia 110mm, seven sieve trays

|

| Pressure Gauge |

Bourdon type, 0-2 kg/cm2

|

| Condenser |

Shell & Tube type made of Stainless Steel.

|

| Bottom Product Tank |

Made of Stainless Steel, Capacity 5 Ltrs.

|